A SCIENTIFIC CHALLENGE

ENTRIES ACCEPTED UNTIL JANUARY 29TH 16:00 CET

Over the past few years, a research project (HORVITAL) involving teams from the Universitat Politècnica de Catalunya, Universitat dels Illes Balears, Universidad Politécnica de Valencia and Universidade da Coruña has been carried out to improve analytical models for the prediction of shear strength in structural concrete elements.

As a part of this project, the Universidade da Coruña team has been assigned, among other tasks, to perform failure tests on a series of beams with 1.00 m, 1.50 m and 2.00 m depths and different combinations of transverse reinforcement. The 1.00 m and 1.50 m tests have already been performed, and results will soon be made available to the scientific and engineering community at the 2020 FIB Conference in Shanghai.

At present, the UDC team is getting ready to start testing on the 2.00 m deep, 12.00 m long, 0.24 m wide beam series. These were built in a prefabrication plant, with the UDC team carrying out careful quality control and assessment.

Figures 1 and 2 show the characteristics and loading arrangement for the test. Concrete mechanical properties were measured on 150 mm x 300 mm concrete cylinders; results are shown in Table 1.

Tabla 1. Concrete properties

| Age (days) |

Average compressive strength (MPa) |

Average indirect tensile strength (MPa) |

Young’s modulus (MPa) |

| 28 días | 48.92 | 4.17 | 31983 |

| 120 días | 55.52 | 4.49 | - |

Table 2 shows the mechanical properties for steel reinforcement.

Tabla 2. Reinforcing steel properties

| Diameter (mm) | Area (mm2) | Yield strength fy (MPa) |

Failure strength fu (MPa) |

Failure strain esu (%) |

| 8 | 50.26 | 575.52 | 687.88 | 10.02 |

| 16 | 201.06 | 550.26 | 670.01 | 13.78 |

| 20 | 314.16 | 543.84 | 681.00 | 13.42 |

| 32 | 804.25 | 546.08 | 671.67 | 12.83 |

Testing is to be carried out on January 29th, 182 days after casting of the beam.

The members of the HORVITAL project would like to raise a challenge for the whole of the scientific and Engineering community. We would be thrilled if you could send us your predictions for the failure load of the beam that will soon be tested. In particular, we would like to pose the following questions:

- Which value of the applied load (in addition to self-weight) will cause failure of the specimen?

- What will be the distance between the axis of the support and the intersection of the critical crack with the bottom face of the beam (see Figure 3)?

- What have been your hypotheses and computational model? Please describe with as much detail as possible.

ANSWER TO QUESTION: BEARING PLATES

As a reply to a question posed by a contestant, we would like to add some information concerning the characteristics of the bearing plate.

- Steel: S355 quality (equivalent to US A572Gr50)

- Dimensions: 25 mm thickness, 300 mm length and 200 mm width (see Figure 4)

- The cylinder is placed aligned with the transverse axis of the plate, 100 mm away from the beam end.

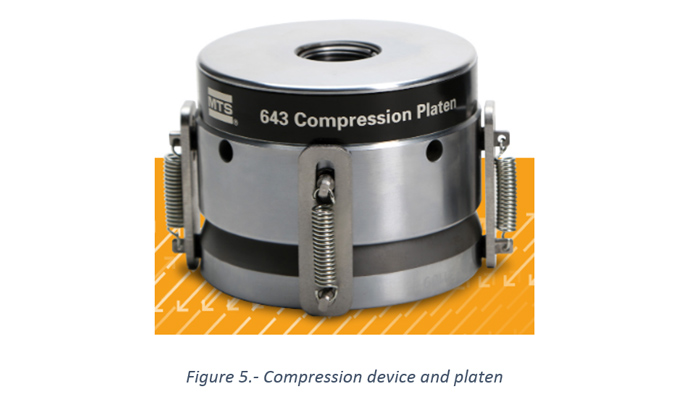

The loading plate has the same characteristics, and pressure is applied on it with a 200 mm-diameter spherical compression platen such as the one shown in Figure 5.

ANSWER TO QUESTION: VERTICAL DISTANCE BETWEEN f32 BARS

The clear vertical space between the 32 mm bars is also 32 mm.

ANSWER TO QUESTION: MAXIMUM AGGREGATE SIZE

Maximum aggregate size is 20 mm.

ADDITIONAL INFORMATION: DEADLINES, QUESTIONS AND DISTRIBUTION

Since we will carry out the test on January 29th 2020, your predictions should be submitted before that date in order to be considered for the contest. Please address your entries or any further questions to any of the following e-mail addresses, stating your name, company or university and position:

Fernando Varela Puga (f.varela.puga@udc.es)

Manuel F. Herrador (mherrador@udc.es)

Fernando Martínez-Abella (fmartinez@udc.es)

A report with the received proposals will be drawn up and published on the university web, university social media and (if possible) in a research journal. Before publication we will ask the participants whether they want to be kept anonymous or not in the published report.

ACKNOWLEDGEMENTS

Project HORVITAL has been funded by the Ministry for Science, Innovation and Universities, Government of Spain (Ministerio de Ciencia, Innovación y Universidades del Gobierno de España) within the 2015 Proyectos I+D+I del Programa Estatal de Investigación, Desarrollo e Innovación Orientada a los Retos de la Sociedad program. This project is coordinated between the Universitat Politècnica de Catalunya (coordinators, BIA201564672-C4-1-R), Universidade da Coruña (BIA201564672-C4-2-R), Universitat de les Illes Balears (BIA201564672-C4-3-R) and Universidad Politécnica de Valencia (BIA201564672-C4-4-R).

The Principal Investigators of the coordinated project are professors Antonio R. Marí Bernat and Jesús Miguel Bairán García (UPC). The PIs of the UDC subproject are professors Manuel F. Herrador and Javier Eiras-López.

The HORVITAL-UDC subproject team includes also the following researchers: professors Fernando Martínez-Abella, Diego Carro-López, Guillermo Alonso-Carro and Sindy Seara-Paz. The other members of the Construction Group (gCons, https://gcons.udc.es, led by prof. Martínez-Abella) involved in the project are Miguel López-López, Manuel Paredes-González and Emilio Rey-Bouzón. Graduate Student Researcher Fernando Varela-Puga (gCons) is carrying out his PhD dissertation within the frame of the project.

The HORVITAL-UDC tests are carried out in the Construction Laboratory of the Center for Technological Innovation in Construction and Civil Engineering (Centro de Innovación Tecnológica en Construcción e Enxeñaría Civil, CITEEC, http://www.agrupacionciteec.udc.es/), at the Universidade da Coruña.

The beams tested in the HORVITAL-UDC subproject experimental campaign have been built thanks to the generous collaboration of the prefabrication company PRECON S.A.U. (https://www.preconsa.es/en), which have made their wonderful personnel and their installations at the Vilagarcía factory (Carretera Vilagarcía-Pontevedra s/n, km 16, 36616 Vilanoviña, Meis, Pontevedra, Spain) available to HORVITAL researchers.

The video shows the unloading and stacking of the beams in the laboratory.